Tune your engine- and vehicle parts!

Use the advantage of residual compressive stress!

Shot peening and/or vibratory grinding will increase the resistance to all requirements of your engine- and vehicle parts. We are working with highly skilled labour and at the highest technical standard. We stand for high customer orientation, guarantee a high quality execution and short delivery times.

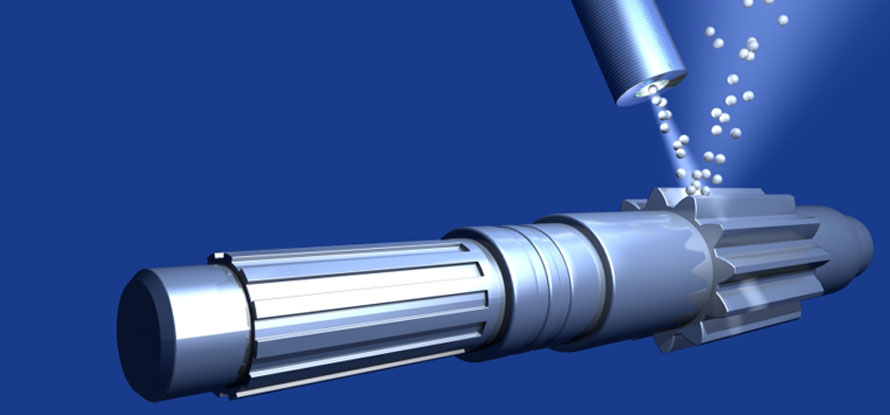

Shot Peening

Shot peening generates high compressive residual stress in the suface layer of metallic parts. The fatigue strenght and the resistance to stress corrosion cracking and corrosion fatigue will be very much increased and the formation and propagation of cracks will be prevented or at least delayed …

Vibratory Grinding

Vibratory grinding polished, smoothed, deburred and chamfered metallic parts with small specially sized, shaped and adapted grinder stones. Unacceptable roughness caused by shot peening, metal spray coatings etc. will be removed or smoothed …

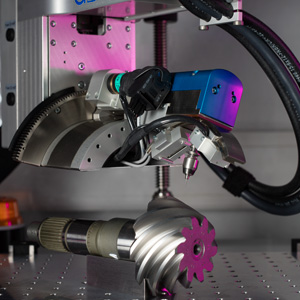

Residual Stress Analysis

The radiographic residual stress analysis is the proof of quality of the existing residual stress values of metallic parts before and after shot peening …

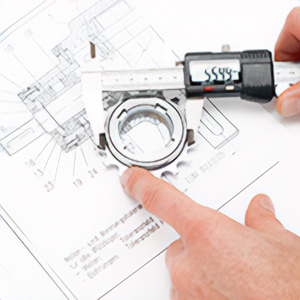

Quality Management

Quality Assurance during and after the shot peening and/or vibratory grinding process your parts are subject to a rigid quality control …