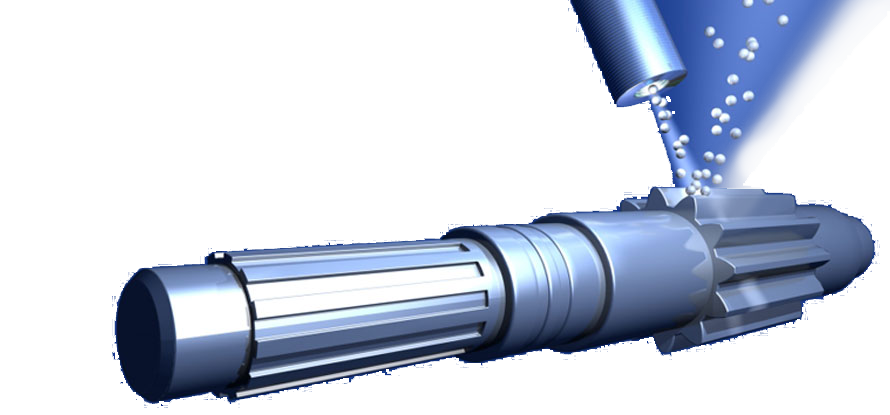

Shot peening is increasing the operating resistance and the fatigue life of your parts

The guarantor of success in shot peening and other blasting applications stand for efficacy, productivity, operating efficiency and cost effectiveness.

In order to meet all requirements of metallic parts it is necessary in many applications to increase the operating resistance and the fatigue life as well as to have a higher safety margin of your parts.

With normal blasting applications and special shot peening you obtain:

- advantage in competition by a higher valency of your final product

- improvement in the reputation of your products

- cost savings by guaranteed values and service

- increased fatigue life of your parts

- higher safety margins of your components

- reinforcement of already designed components without changing materials or dimensions.

The process is applicable at all metallic parts

Examples of Application

Motor Vehicles

- Vehicles and agricultural machines: axle shafts, gear shafts, drive shafts, cardan shafts, planetary gears, gear wheels, forked axles, cardan joints, pinions, universal joint yokes, king pins, shift linkages, rods, tubo-supercharger turbine blades, clutch facing springs, clutch gears, clutch disks, tow hooks for trailers, leaf springs, rims.

- Drive units and gearing: gear wheels, pinions, internal geared wheels, ring gears, worm pinions, worm wheels, hypoid bevel gears, cylindrical lantern gear wheels, input and output shafts, propellers.

- Combustion engines: connecting rods, cylinder liners, rocker arms, valve springs, valve tappets, crank-shafts, camshafts, pistons, piston heads, piston pins, chain wheels, link plates, pins.

Aviation and Space Travel

- Aviation and space travel: turbine blades, turbine blisks, compressor blades, propeller blades, fastening elements, gears, pinions, internal geared wheels, ring gears, worm pinions, worm wheels, hypoid bevel gears, cylindrical lantern gear wheels, input and output shafts, landing gears, airfoils, flaps, actuating drives, wheel-rims.

Power Engineering

- Steam-, gas, wind- and hydroelectric plants: turbine disks, turbine blades, turbine rotors, heat exchangers, wind power wheels, gearing.

Machinery & Facility Engineering

- Compressors and pumps: housings, impellers, distributors, valve glands, valve reeds, valve chambers, valve faces, shafts, crankshafts, pistons, cylinders, gear shafts.

- Machine parts: extruder shafts, extruding shafts, feed screws, worm casings, threaded spindles, anti fatigue shafts, dowel screws, splines, torsion bars, springs of all kind, membranes, dies, bearing housings, ball races, ball retaining rings, components of stamping machines.

Tool Manufacturing

- Electrical and pneumatic tools: cylinders, jackets, percussion pistons, anvils, dies, pins, drivers, housings, tappets, percussion drills, boring bits, bore crowns, sleeves, sockets.

Chemical Industry

- Chemical equipment: centrifuges, mixers, driers, spiral conveyors, oscillating conveyors, heat exchangers, columns, containers, vessels, pressure tank, storage tanks, compensators, components of pumps, agitators, stirrers, paddles, impellers, fans, valves, pipework.

Oil- and Gas Extraction and Mining

- Drill technology: pipes and welded components, pipe strings, brackets, bits, stock boxes.

Medical Technology

- Prosthesis: thighbone prosthesis

Dental: drill gears

Other Applications

- Roughening, smoothening, burnishing, superficial structuring, matting, deburring, engraving, descaling, skiving, clean blasting, frettling, decontaminating, peen forming, straightening.