Determining the Shot Peening Intensity and the Coverage of Shot Peening

Definition for the Shot Peening Intensity

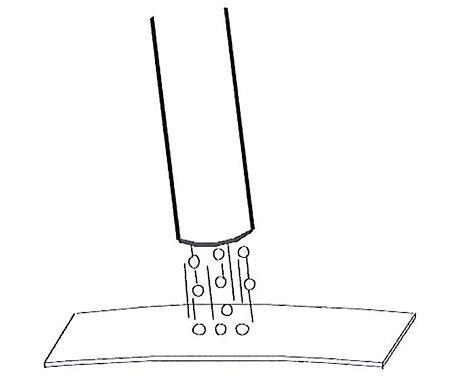

If an Almen test strip is shot peened up to a shot peening coverage of approx. 98 % on one side only, it will be curved, depending on the grade of plastic deformation and compression caused by the energy of the shot peening media stream.

The grade of plastic deformation and compression depends on the:

- density of the shot peening media

- velocity of the shot peening media

- angle of impact of the shot peening media

- shape of the shot peening media

- flow rate of the shot peening media (amount of impacts)

- hardness of the shot peening media

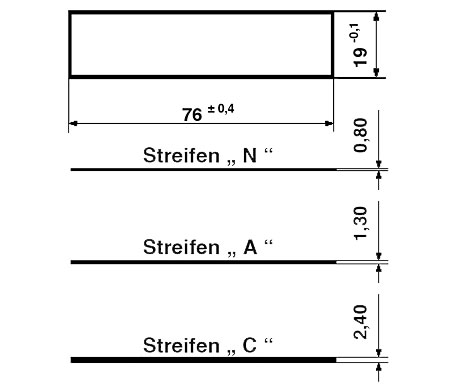

The shot peening intensity is defined as the arc height of an Almen test strip measured at a coverage of approx. 98 % by using an Almen gauge.

Definition for the Coverage of Shot Peening

The shot peening coverage means the percentage of the surface actually impacted by the shot peening process (dimpled or obliterated surface). A coverage of 100 % is only a theoretical limit and is neither realizable nor measurable. In the shot peening process a coverage of approx. 98 % is mandatory.

Attention!

Each changing or variation of parameters in this determination process for the right shot peening coverage is changing the nessesary time of shot peening und requires a new determination of shot peening coverage.

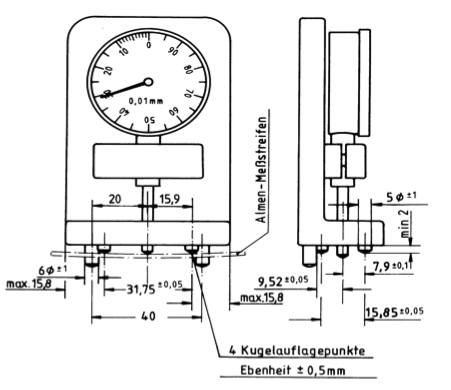

Almen Gauge

The Almen gauge is used to measure the arc height of an Almen test strip at four defined points.